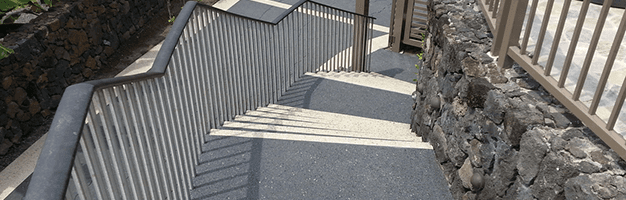

No warp, no rot and no splinters. That's right, this is all created using Concrete Technology of Hawaii's modified concrete systems. Its all custom textured and colored by hand. The wood look is available indoors and out. It can be applied with a rough texture or a smooth high gloss finish. With all the durability of our custom concrete systems and available in countless color combinations, the wood look is an exciting new addition to our line of applications.

Concrete Technology of Hawaii's Reflective Floor System is a relatively new product in our line of floor coatings. Ideal for home, commercial and industrial interiors, this super fast curing epoxy coating is highly durable and absolutely stunning.

Utilizing our Rapid Armor (soon to be EZ Armor) epoxy, the Reflective Floor System achieves a smooth, high gloss finish with a beautiful 3 dimensional effect within. The pictures don't really do it justice, but I'll do my best to explain the product, some benefits, a little about the application process and show you a few examples along the way. Be sure to check out the video at the end of this post.

Utilizing our Rapid Armor (soon to be EZ Armor) epoxy, the Reflective Floor System achieves a smooth, high gloss finish with a beautiful 3 dimensional effect within. The pictures don't really do it justice, but I'll do my best to explain the product, some benefits, a little about the application process and show you a few examples along the way. Be sure to check out the video at the end of this post.

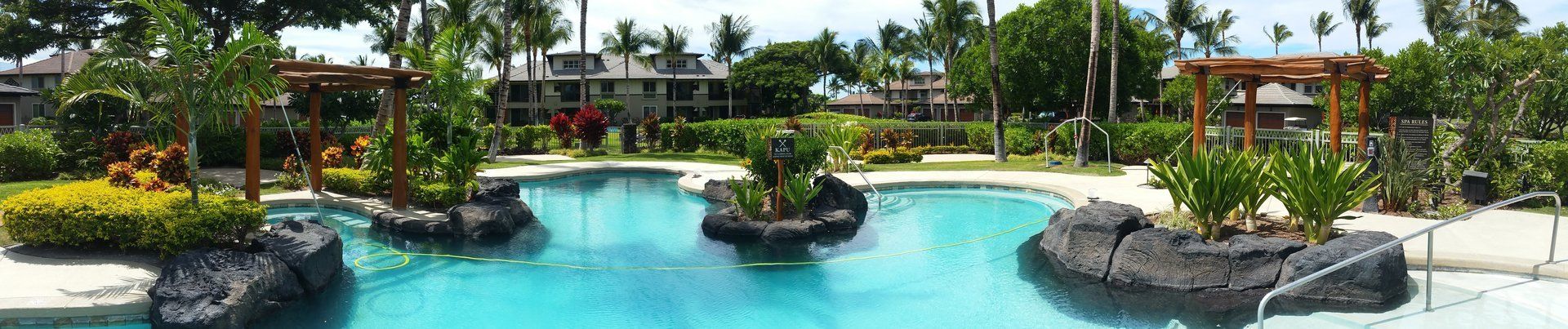

This week we have Concrete Technology of Hawaii's Stone Classics System. This one is similar to the Acrylistain system in its application with some differences in the coloring techniques. We utilize the same materials as the previous 2 systems; Hallmark and Acrylistain, so once again you get all the benefits of our polymerized acrylic concrete coatings without the cost and headaches of actual stone. All of CTi's colors are available as well as custom colors so we can compliment some of the colors in and around the home or business or we can come up with something totally unique and custom. Twice the strength of standard concrete and resistant to UV, fade, chemicals and staining. This alternative to stone stands the test of time.

Next up is the Acrylistain system. This is Concrete Technology of Hawaii's take on stained concrete, but taken to a higher level. Unlike lithochrome or acid staining, we're not staining the original grey concrete, nor does the slab need to be new or fresh to accept the color. We actually use our polymerized acrylic concrete as a canvas for staining. All of CTi's colors are available, as well as custom ordered colors.

Over the coming weeks, I plan to outline our different products here in this blog. Seeing as we've started this year with a number of garages, I thought I'd begin this series with a few of them and our Durafleck 5000 product line.

We can apply any one of our different products to a garage floor, but I usually recommend the Durafleck 5000 system for its ease of cleaning, resistance to chemicals and obviously visually pleasing, granite-like appearance. Like many of our other products, it is great in other parts of the home and commercial areas as well. Kitchens, basements, hospitals and workshops can all benefit from this durable coating. Its available in about 30 different standard color combinations, but custom colors are available upon request as well.

We can apply any one of our different products to a garage floor, but I usually recommend the Durafleck 5000 system for its ease of cleaning, resistance to chemicals and obviously visually pleasing, granite-like appearance. Like many of our other products, it is great in other parts of the home and commercial areas as well. Kitchens, basements, hospitals and workshops can all benefit from this durable coating. Its available in about 30 different standard color combinations, but custom colors are available upon request as well.

Welcome to the newly designed Concrete Technology of Hawaii Inc. website. We're excited about the new look and hopefully a more streamlined experience navigating our site. I'm still in the process of migrating over some of our best content from the old site as well as updating some of our more recent work.

I plan to use this space to share information regarding our specific overlay systems, new products and current jobs. Feel free to comment with any questions and I'll do my best to answer in a timely manner. A lot of questions can be answered in our FAQ's section, so be sure to check that out.

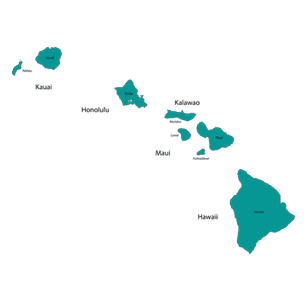

Finally, we will once again be attending The Kona-Kohala Building and Design expo at the Sheraton Hotel in Keauhou. However, said expo has been renamed as The Hawai'i Island Living + Design Show. It takes place on February 17 & 18. I hope to have a few new sample boards for the show and its a great chance to get hands on with our amazing products. So stop by, talk story and see how Concrete Technology of Hawaii Inc. can transform your dull, grey concrete into a work of art.

I plan to use this space to share information regarding our specific overlay systems, new products and current jobs. Feel free to comment with any questions and I'll do my best to answer in a timely manner. A lot of questions can be answered in our FAQ's section, so be sure to check that out.

Finally, we will once again be attending The Kona-Kohala Building and Design expo at the Sheraton Hotel in Keauhou. However, said expo has been renamed as The Hawai'i Island Living + Design Show. It takes place on February 17 & 18. I hope to have a few new sample boards for the show and its a great chance to get hands on with our amazing products. So stop by, talk story and see how Concrete Technology of Hawaii Inc. can transform your dull, grey concrete into a work of art.